PVC is polyvinyl chloride and PE is polyethylene. The pipe connection of two different materials requires pipe fittings. HDPE pipe and PVC pipe can use threaded connection or flange connection.

What is PVC?

The full name of PVC is polyvinyl chloride. Its main component is polyvinyl chloride, and other components are added to enhance its heat resistance, toughness, ductility, etc. The top layer of this surface film is lacquer, the main component in the middle is polyvinyl chloride and the bottom layer is back-coated adhesive. It is a kind of synthetic material that is well-loved, popular and widely used in the world today.

How to Distinguish PVC Pipe?

Nowadays, more and more people use PVC hoses in survival production. The tension of PVC hoses is composed of polyvinyl chloride. Other factors have been mixed to improve its flexibility, heat resistance, plasticity and so on. It is a plastic product and it can use raw materials more effectively. Compare with other plastic products, PVC has an energy-saving effect. At the same time, PVC hose is more effective than other plastic products. The energy consumption of other plastic products is much lower, and even if it is discarded, it can also be reused, ignition or energy, etc.

A stabilizer is added to PVC at the factory, but there are lead-free and lead-free stabilizers. If it is mixed with a stabilizer such as lead salt, it will give rise to great hidden dangers. Some small companies use lead salt as a stabilizing agent in order to save costs. The pipes produced in this way will cause excessive levels of heavy metals in drinking water and cause harm to the human body. If this kind of pipe is buried underground, this piece of soil will become excessively heavy metals.

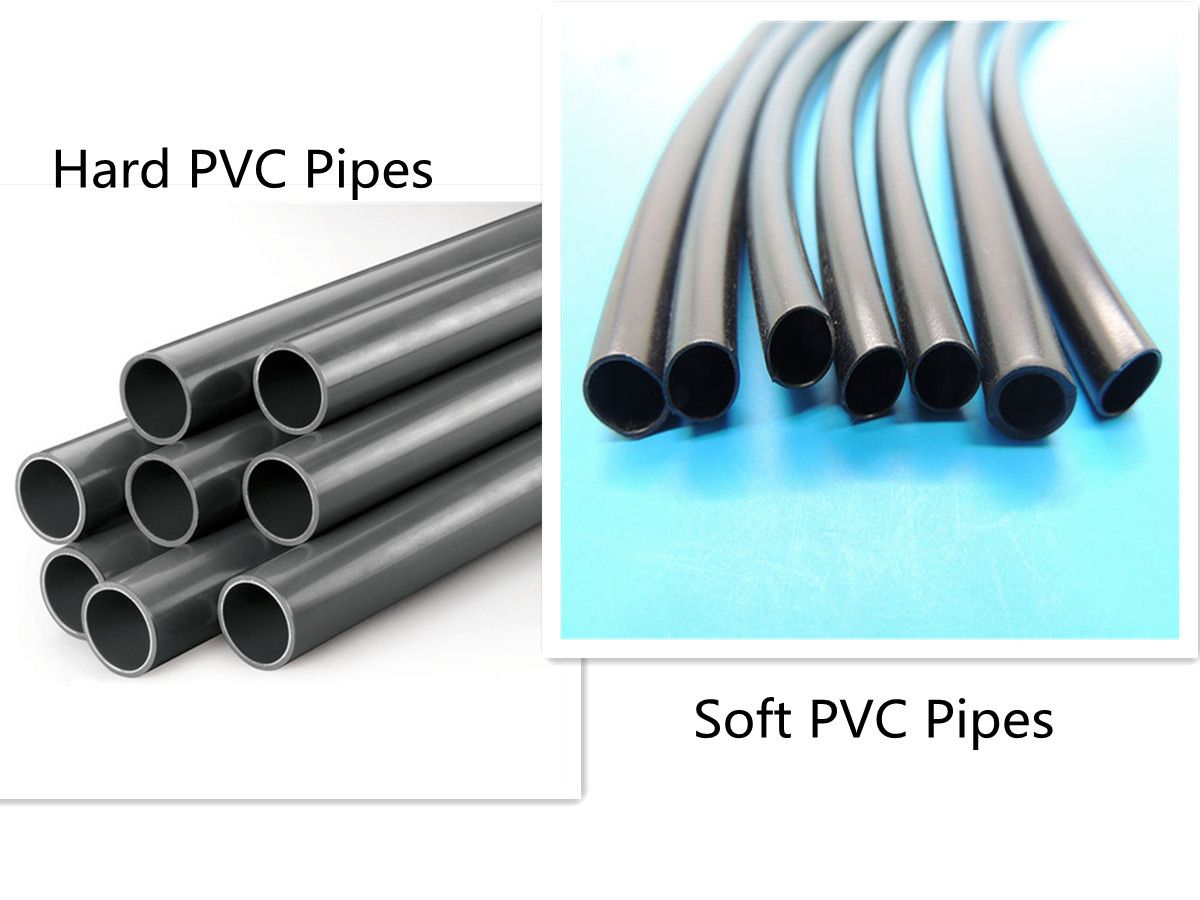

In terms of classification, PVC can be divided into soft PVC and hard PVC. Hard PVC accounts for about 2/3 of the market, and soft PVC accounts for 1/3. Soft PVC is generally used for floors, ceilings and leather surfaces. The difference between soft and hard PVC is that soft PVC has a softener factor. Therefore, soft ones tend to become brittle and hard to survive. However, the hard tube is flexible, easy to shape, not easy to be brittle, non-toxic and pollution-free, and has a longer survival time.

Features of PVC Pipe

1. Light Weight, Convenient Handling and Unloading

PVC pipe material is very light. It convenient for handling and construction, which can save labor.

2. Excellent Chemical Resistance

PVC pipe has friendly acid resistance, alkali resistance and corrosion resistance, which is very suitable for the chemical industry.

3. Small Fluid Resistance

The wall surface of PVC pipe is smooth and its resistance to fluid is small. Its roughness coefficient is only 0.009, which is lower than other pipe materials. Under the same flow rate, the pipe diameter can be reduced.

4. High Mechanical Strength

PVC pipe has good water pressure resistance, external pressure resistance, impact resistance, etc. It is suitable for piping projects under various conditions.

5. Good Electrical Insulation

PVC pipe has excellent electrical insulation. It is suitable for conduits of wires and cables and wire piping in buildings.

6. Does Not Affect Water Quality

PVC pipes are proved by the dissolution test to not affect water quality. They are the best pipes for tap water piping at present.

7. The Construction is Simple

The joint construction of the PVC pipe is quick and easy, so the construction cost is low.

What Are The Main Applications of PVC Pipes?

The essence of PVC pipe is a kind of vacuum blister film, which is used for the surface packaging of various panels. So it is also called decorative film and adhesive film, which is used in building materials, packaging, medicine and many other industries.

Proportion of Application Areas

- The building materials industry -- About 60%,

- The packaging industry -- About 30%

- Several other small-scale applications -- About 10%

PVC pipes are divided into two types: PVC water supply pipes and drainage pipes. They are used in municipal water supply and drainage, industrial water supply and drainage, civil water supply and drainage, irrigation, vegetation watering, etc.

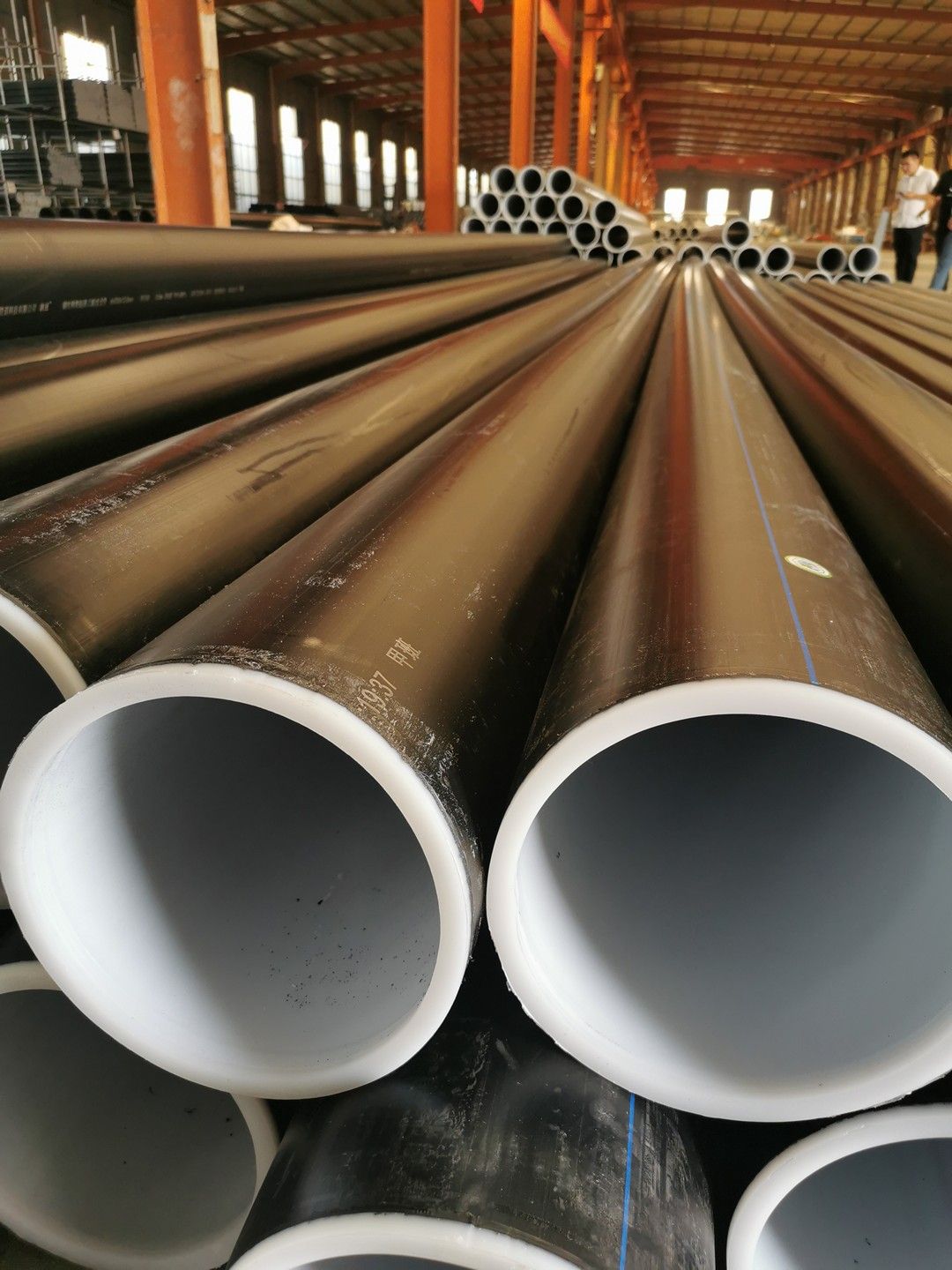

Simply Introduction of PE Pipe

The chemical name of PE is polyethylene. PE material is widely used in the field of water supply pipe manufacturing due to its high strength, high temperature resistance, corrosion resistance and non-toxicity. Because it will not rust, it is an ideal pipe to replace ordinary water supply pipes. PE supply water pipes are the replacement products of traditional steel pipes and PVC drinking water pipes.

PE pipe must bear a certain pressure. So usually PE resin with large molecular weight and good mechanical properties, such as HDPE resin (high-density polyethylene resin) should be used. HDPE resin has low tensile strength, differential pressure resistance, poor rigidity, poor dimensional stability during molding and difficult connection. It is not suitable as a material for water supply pressure pipes. However, due to its high sanitary indicators, HDPE especially HLDPE resin has become a common material for the production of drinking water pipes. HDPE and LLDPE resins have low melt viscosity, good fluidity, and easy processing, so their melt index can be selected in a wide range, usually MI is between 0.3-3g/10min.

Plastic pipes are developing steadily. PE pipes, PP-R pipes and UPVC pipes all occupy a place. Among them, the strong development momentum of PE pipes is the most remarkable. PE pipes are used in a wide range of fields. Water supply pipes and gas pipes are its two largest application markets.

If you want to know more about PE Pipe, please click here!

How to Connect PVC Pipe With PE Pipe?

Due to the different materials, HDPE pipes and PVC pipes cannot be bonded by hot melt or glue.

HDPE pipe and PVC pipe can use threaded connection or flange connection.

Threaded Connection: heat-melt one end of the HDPE pipe with an HDPE inner wire directly (or outer wire directly), then glue one end of the PVC pipe to an outer wire directly (or inner wire directly), and then screw the inner and outer wires directly together.

Flange Connection: Hot-melt the HDPE flange and HDPE pipe, bond the PVC flange and PVC pipe, and then fasten the two flanges with screws.

No matter what method is used, you must be careful not to forget to put the gasket or wrap the sealing tape.