Intro

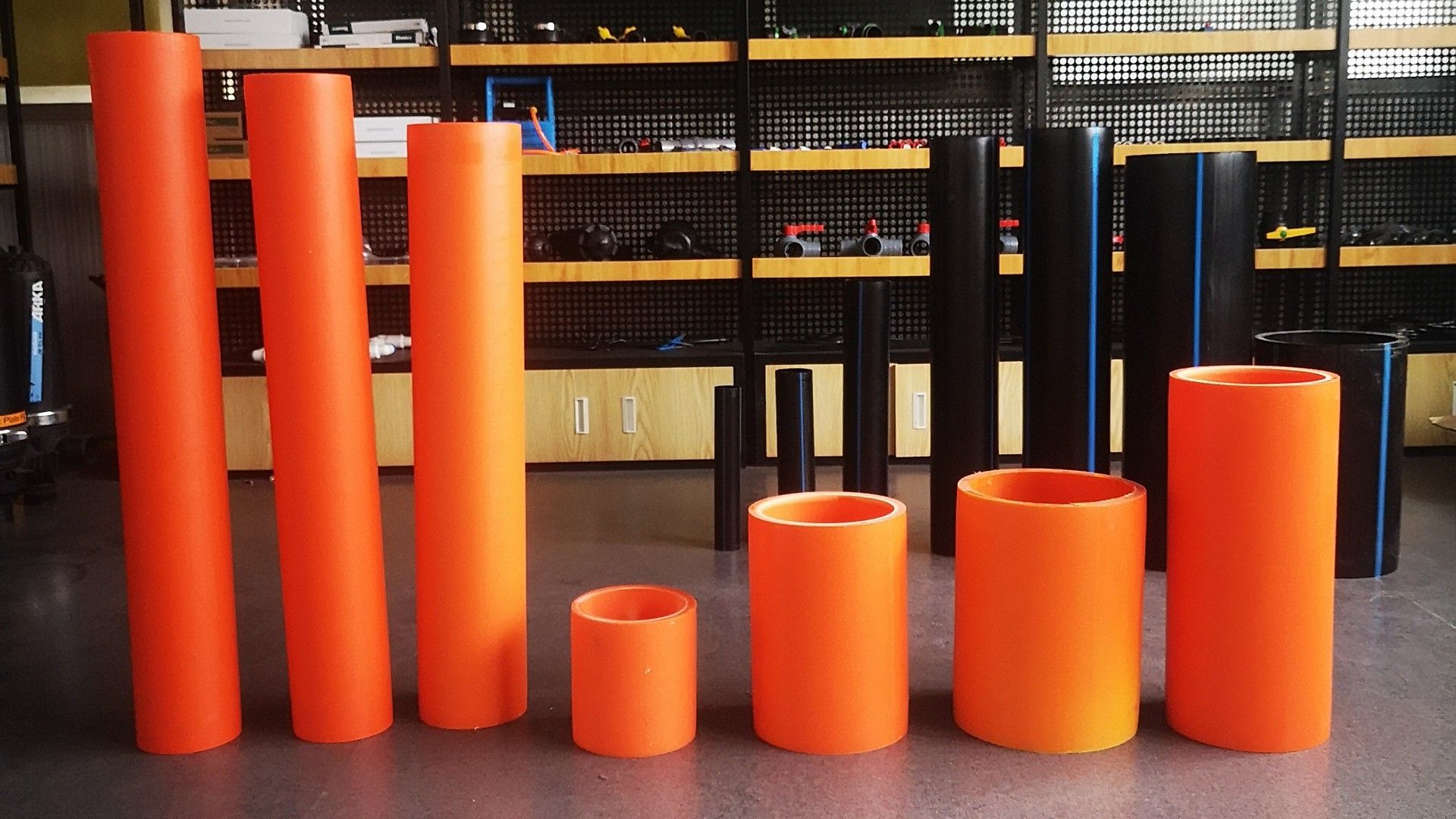

MPP electronic pipe is also known as the power cable protection tube, it uses the modified polypropylene as the main raw material, and with the characteristic of resistance to high temperature and external pressure, it is often used in pipeline projects such as municipal and telecommunications.

MPP electronic pipe is an ideal pipe candidate for construction projects where laying pipes and cables in such as roads, railways, buildings, and river beds without a large amount of dredging, soil excavation and road damage.

Application

- Widely used in pipeline projects such as municipal administration, telecommunications, electricity, gas, tap water, and heat.

- Urban and rural trenchless horizontal directional drilling power piping engineering, and lighting excavation power piping engineering.

- Urban and rural non-excavation horizontal directional drilling sewage drainage pipe engineering and industrial wastewater discharge engineering.

Performance & Advantages

- MPP electronic pipe has excellent electrical insulation.

- MPP electronic pipe has high heat distortion temperature and low temperature impact performance.

- MPP electronic pipes have higher tensile and compressive performance than HDPE.

- MPP electronic pipes are light, smooth, low friction resistance, and can be welded using butt welding.

- The long-term use temperature of MPP electronic pipes is

5 ~ 70℃.

MPP Pipe Construction Instructions

- MPP electronic pipes are strictly prohibited from throwing, hitting, scratching, or exposing them during transportation and construction.

- When the MPP electronic pipe is hot-melt butt-joined, the axis of the two pipes should be aligned, and the end face should be cut vertically and flat.

- MPP electronic pipes process temperature, time, pressure, and adjust accordingly depending on the weather conditions.

- The minimum bending radius of MPP electronic pipes should be ≥75 pipe outer diameter.

110mm ~ 250mm, divided into normal type and reinforced type. The ordinary type is suitable for excavation and laying construction and trenchless crossing construction with a buried depth of less than 4M; the reinforced type is suitable for trenchless crossing construction with a buried depth greater than 4M.