Usually when the PE Pipe get dirty, we will need to clean it. And when cleaning is required, how to clean and what tools or machines can be used for pipe cleaning?

There are two types of machines in the China market: high-frequency machines and pulse machines to clean pipes.

High-frequency Cleaning Machine

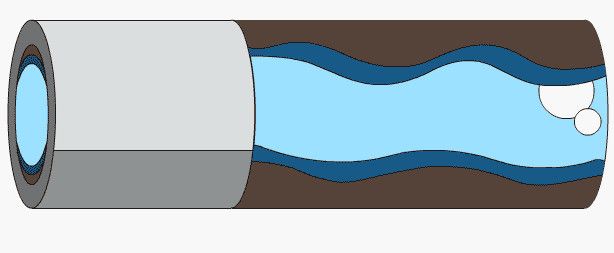

High-frequency water pipe cleaning machine is also called water cycle water pipe cleaning machine. It pumps high-pressure air into the pipeline to produce water hammer, and then stop injecting high-pressure air. Due to the water hammer effect of pipeline pressure, the water moves back and forth in the pipeline which is also called reverse washing. The opening and closing constitute a kind of cycle which is named stable frequency.

Pulse Cleansing Machine

As its name, pulse cleaning machine is a kind of machine that uses pulse controller to spray air-water mixture into water pipe at high speed, scour and vibrate the hook and sediment on the inner wall of water pipe, so as to peel off dirt and discharge it out of water pipe.

What is the Difference Between High-frequency Machines and Pulse Machines?

Working Principle

High frequency refers to electromagnetic waves with a frequency greater than 100 kilohertz, also called high frequency. It is a continuous wave and the waveform is a pure sine wave. It also does not contain any harmonics and it can transform different bands. It uses water and high-frequency gas produce an air-burst effect in the pipeline, and the principle of water hammer breaks the rust, sand, heavy metal, etc. attached to the pipeline into small particles and flows out of the water hose with the water flow head.

The pulse is a discontinuous wave and the waveform is a sharp wave with a large number of odd harmonics. It is used to trigger other control circuits or for frequency multiplication. There is only one band. Because the pulse cannot reach the same high frequency of high frequency machines, it just has only one band, it cannot clean the dirt on the inner wall of the pipeline. The cleaning purpose can only be achieved by adding citric acid to corrode the dirt on the inner wall of the pipeline. The pulse can only play the role of flushing the dissolved citric acid in the pipeline.

Operation Difference

1. Prepare tool comparison

Tools are required for high cycle (pure physical cleaning):

- High cycle cleaning machine

- Air compressor

- A complete set of kits

Pulse citric acid needs tools:

- Pulse machine

- Air compressor

- Kit

- Citric acid (depending on the length of the customer's pipe)

- A large bucket for dissolving citric acid

- Hot water (it is necessary to boil water to dissolve citric acid, which requires high temperature).

2. Operation Process

High cycle cleaning process:

- Check the water route and the high cycle wave will follow the water flow.

- Connect the machine.

- Start up cleaning (the machine is equipped with pressure gauge and output pressure gauge in the pipeline, so there is no need to worry about pressure control problem at all)

- The water is clean and the cleaning is over.

Pulse Citric Acid Cleaning Process:

- Check the pipeline.

- Dissolve citric acid with boiling water.

- Close the main water valve.

- Connect the machine.

- Drain the residual water of the pipeline.

- Leakage measurement.

- Release pressure and extract liquid, and inject the commissioning citric acid solution into the pipeline.

- Soak for half an hour or more.

- Impulse citric acid solvent out of the pipe.

Construction Difference

In the construction of pure physical high frequency equipment, the main water valve does not need to be closed. The water consumption of other floors and rooms is not affected and no solvent needs to be added in the cleaning process. The distance between the branch pipe and the washing pipe is 300 meters. It is short time, easy operation, water saving, environmental protection and there is no residue.

In the construction of pulse citric acid, the water valve should be closed. Attention should be paid to the proportion of citric acid debugging. High concentration corrodes the pipe wall, low concentration cannot be cleaned, so the dosage cannot be controlled scientifically. At the end of cleaning, each tap should be drained for a few minutes to ensure that the citric acid is washed clean without residue and odor.

Above introduce two cleaning machines (high-frequency machines and pulse machines t) to clean PE Pipes. If you want to know more, please click How to Clean PE Pipe?.

In addition to cleaning, daily maintenance is also very important during the use of PE pipes. Here are some points that need to be paid attention to in daily maintenance of PE pipes.

- PE Pipe install on the road, it is strictly forbidden to climb and tie heavy objects on the pipeline.

- It is forbidden to use sharp tools to cut or scratch the surface of the pipe.

- Ensure the correct water supply pressure to prevent sudden accidents. 4 When open various valves of the main and branch pipeline network, it should be slow. Because the impact of the rapid water flow on the entire pipeline will cause large vibrations, which will affect the service life of the pipe.

When the PE pipe is damaged in operation, the valve should be closed first and the water source should be cut off. If the damage range is very small, the simplest method is to cut the damaged part and add another directly to achieve the purpose of repair. If the damage range is large, the damaged pipe section must be cut off and the pipe section must be directly connected with PE fitting.