Common building water supply and drainage pipes mainly include plastic pipes, metal pipes and composite pipes. But in fact, far beyond these categories, there are more new types of pipes. Here we will introduce the part 1 of Building Water Supply and Drainage Pipes to you. They are Steel pipe, Water supply plastic pipe, PVC pipe, Copper pipe and Composite pipe.

1. Steel Pipe

Steel pipes include ordinary steel pipes, galvanized steel pipes and seamless steel pipes. Ordinary steel pipes are used for non-domestic drinking water pipes or general industrial water supply pipes. Galvanized steel pipe surface (produced by hot-dip galvanizing process) is to prevent rust and corrosion, so as not to affect water quality. It is suitable for drinking water pipes or some industrial water pipes with high water quality requirements. Seamless steel pipes are used for high-pressure pipe networks. Its working pressure is above 1.6MPa.

Connection Methods

The connection methods of steel pipes include threaded connection, welding and flange connection. Threaded connection is the use of threaded pipe fittings. Most of the accessories are made of malleable cast iron, divided into galvanized and non-galvanized, and their corrosion resistance and mechanical strength are relatively large. Currently there are few steel parts. Galvanized steel pipes must be connected by threads, and their fittings should also be galvanized fittings. This method is mostly used for surface installation of pipelines. Welding is to connect two sections of pipelines together with welding machine and welding rod. The advantages are tight joints, no water leakage, no accessories, and rapid construction. But it cannot be disassembled. Welding is only suitable for non-galvanized steel pipes. This method is mostly used for concealed pipelines.

The flange is connected to a pipe with a larger pipe diameter (above 50m). The flange is often welded (or threaded) on the pipe end, and then the two flanges are connected together with bolts. The two pipes are also Connected together. Flange connections are generally used to connect valves, check valves, water meters, pumps, etc., as well as pipe sections that need to be disassembled and overhauled frequently.

2. Water Supply Plastic Pipe

The most commonly used water-supply plastic pipes are water-supply unplasticized polyvinyl chloride pipes (UPVC) and water-supply polypropylene pipes (PP pipes). In addition, there are polyethylene (PE) pipes, which are suitable for conveying water with a temperature not exceeding 40°C. The relevant standards follow the requirements of "Polyethylene (PE) Pipes for Water Supply" GB/T13663; cross-linked polyethylene (PE-x) Pipe: Polybutene (PB) pipe, suitable for conveying water at a temperature of 20"-90℃. They all have strong chemical stability, corrosion resistance. And they are not affected by acids, alkalis, salts, oils and other media Corrosion, smooth pipe wall, good hydraulic performance, light weight, easy processing and installation. But the common shortcomings are poor, temperature resistance and low strength. Therefore, the use is also subject to certain restrictions.

Water supply rigid polyvinyl chloride pipe (UPVc), the temperature of conveying water does not exceed 45°C. UPVC pipes generally adopt socket connection, among which socket bonding is suitable for pipe outer diameter 20~1601m; rubber ring connection is suitable for pipe outer diameter greater than or equal to 63mm; connection with metal pipe fittings, valves, etc. adopt thread or flange connection .

Water supply polypropylene pipe (PP pipe) is suitable for the system working pressure is not more than 0.6Mpa, and the working temperature is not more than 70℃. The water-supply polypropylene pipe adopts hot-melt socket connection. When connecting with metal pipe fittings, polypropylene pipe fittings with metal inserts are used as a transition. The pipe fittings and polypropylene pipes are connected by hot-melt sockets, and the metal pipe fittings are connected by threads.

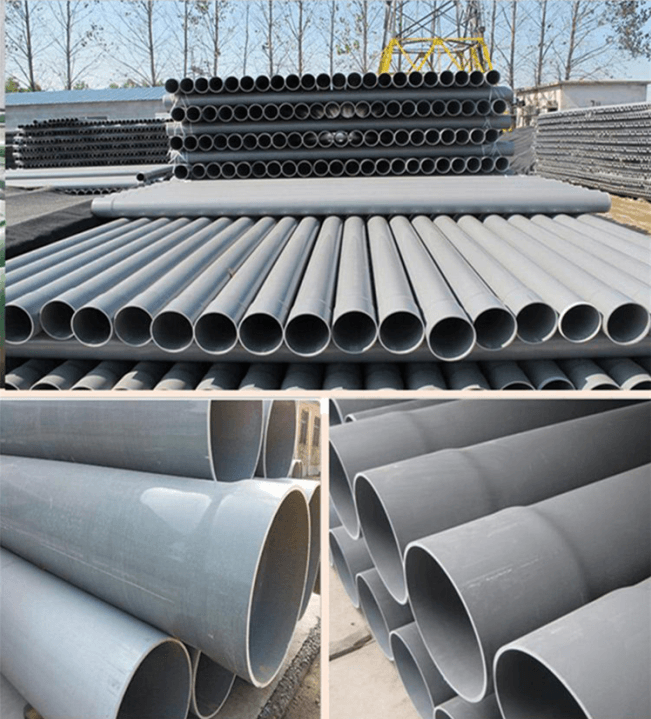

3. PVC Pipe

PVC pipe is a kind of plastic pipe. The joint is generally bonded with glue. Because of its poor frost resistance and heat resistance, it is difficult to be used as hot water pipe. The pipes are easy to break and deform when heated. In most cases, PVC pipes are suitable for electrical threading pipes and drainage pipes.

4. Copper Pipe

Copper pipes and their fittings have complete varieties and specifications. They are with a large diameter range, that can be selected from 6mm to 273mm. The copper pipe is easy to bend, easy to process, easy to change shape, and can meet all the needs of pipeline wiring and interconnection in engineering installation. Especially in the on-site construction, the temporary cutting, bending and polishing of copper pipes are all easy. Various pipes and fittings can be assembled and transported to the site, or they can be temporarily installed on site with satisfactory results.

Copper is a hard metal, which corrodes. It can be used in different environments without damage. Judging from the history of foreign use, the use time of many copper pipes has exceeded the service life of the building itself. Therefore, copper water pipes are absolutely safe and reliable water pipes.

Copper can be said to be a "red metal with a green face". Copper can inhibit the growth of bacteria and keep the drinking water clean. Copper tableware has a long history, non-toxic and tasteless.

Copper pipes and fittings can keep their shape and strength under high temperature and high pressure, and will not have long-term aging phenomenon.

The copper tube has a dense and hard protective layer. No matter it is oil, carbohydrate, bacteria and virus, harmful liquid, air or ultraviolet light can't pass through it, nor can it corrode it and pollute the water quality. The parasite can't live on the surface of copper. But the high price of copper pipe is its biggest disadvantage, which is the most high-grade water pipe at present.

5. Composite Pipe

With the continuous development of China's industry and technical improvement, a large number of new materials and new processes are used in water supply and drainage engineering. Composite pipes are widely used in building water supply engineering.

(1) Aluminum plastic composite pipe

The middle layer of aluminum plastic composite pipe is welded aluminum pipe, and the outer and inner layers are made of medium density or high density polyethylene plastic or cross-linked high density polyethylene by hot melt adhesive. The pipe not only has the pressure resistance of metal pipe, but also has the corrosion resistance of plastic pipe. It is an ideal pipe for building water supply. Aluminum plastic composite pipe is generally crimped by thread ferrule, and its fittings are generally copper products. It is to first cover the fitting nut at the end of the pipe, then cover the inner core of the fitting into the end, and then tighten the fitting and nut with a wrench. Good high temperature resistance, convenient construction, greatly improve the labor efficiency. Due to long-term thermal expansion and cold contraction, the pipe wall will be dislocated, resulting in leakage. Aluminum plastic pipe is easy to burst when pressed. In the area with relatively new decoration concept, the aluminum-plastic pipe has gradually lost the market and belongs to the eliminated products.

(2) Steel-plastic composite pipeline

The steel-plastic composite pipe is a pipe made by lining (coating) a certain thickness of plastic on the inner wall of a steel pipe. Generally divided into two types: plastic-lined steel pipe and plastic-coated steel pipe. Steel-plastic composite pipes are generally connected by threads, and their fittings are generally steel-plastic products.