Tamping pipe construction is a non-excavation construction method. This construction method is to make the pipe level as strong as the soil without excavating the surface soil. The difficulty of this construction method is that the pipe can bypass obstacles and proceed along the designed route. This construction method is most used in large cities. Jacking pipe construction is also a non-excavation construction technology. Let’s introduce them.

Pipe Ramming Method

What is Ramming Pipe Construction?

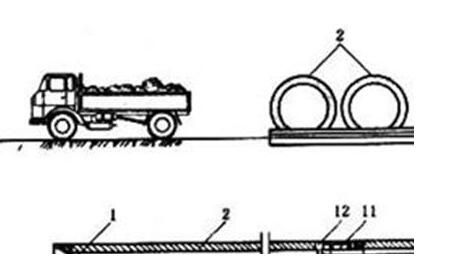

The ramming pipe construction method is a technology that uses a rammer to directly ram the steel pipe to be laid into the ground along the designed route to realize non-excavation pipe laying. The supporting machine of the system has an air compressor, a pipe rammer, a pressure plate with a gripping plate, a conical joint, a dump cone, a tension belt and a cutting pipe head.

Working Principle

The working principle of the rammed pipe construction method is that the large impact force generated by the rammer hammer driven by compressed air directly acts on the back end of the steel pipe, overcomes the friction between the soil layer and the pipe body, and cuts into the soil through the front steel cutting pipe head , The cut soil core is temporarily left in the steel pipe. After the pipe is successfully tamped, remove the cutting pipe head and use air pressure, high-pressure water jet or spiral drill pipe to discharge the soil core.

Applications & Advantages

The rammed pipe construction method is highly adaptable to the ground. It can be used in almost any soil layer except for a large number of rock masses and larger rocks. It can be constructed under the condition of shallow overburden. The pipe-laying diameter range is large, the equipment is simple, the investment is small, the operation and maintenance are convenient, the construction cost is low, the construction accuracy is high, and the level and elevation deviation can be controlled within 2%.

Because the pipe has to withstand considerable impact, the ramming pipe construction method is limited to steel pipe construction. Generally, seamless steel pipes are used, and the wall thickness must meet certain requirements. The pipe diameter ranges from 200-2000mm. The laying length depends on the rammer hammer. Depending on the power, pipe diameter, and geological conditions, it is generally within 80m, and the longest can reach 150m. This method has high efficiency and the construction speed is 15-30m/h.

Pipe Jacking Method

The pipe jacking method can be divided into the following types

- Static pressure type pipe jacking. That is simply using the feed cylinder to push and pull the casing.

- Hydraulic sprint static pressure type pipe jacking. That is the use of high-pressure hydraulic sprint to break the soil, the cylinder pushes the casing, and a small amount of slag is discharged outside the pipe.

- Spiral jacking is a method of construction using augers. During construction, first prepare for jacking into the pit, install the auger drill horizontally in the pit, and then use the auger to transmit the drilling pressure and torque to advance the nose.

Using the jacking cylinder of the drill rig to push the pipe section forward, the soil excavated by the machine head is transported from the pipe to the pit through the spiral drill rod.

The jacking distance of this method is relatively short, and can only be used in straight sections, generally the jacking distance is within 60m. Its advantages are no vibration during construction, low noise, light weight, convenient operation, few construction personnel, and small foundation pit. When the pipe is 2m long, a 3.6m long and 1.5m wide jack can be used.

- Rotary pipe jacking. That is, the drill bit cuts the soil layer, the casing is followed up synchronously, and the slag is discharged inside the pipe. It can be divided into two types: feed water drilling and waterless drilling, and it can be divided into two types: casing rotation and non-rotation.

In the pipe jacking construction technology, the jacking force is an important basis for selecting the construction method, determining the back wall reinforcement plan and determining the construction schedule.

According to construction practice, the static pressure type pipe jacking has the largest resistance and the required jacking force, followed by the hydrostatic pressure type and the rotary type the smallest.

However, the rotary construction method has the highest requirements for the machinery, and the static pressure pipe jacking has the simplest requirements for the machinery.

Therefore, when selecting pipe jacking construction, the appropriate construction method should be selected according to the jacking force and equipment capability required for jacking.