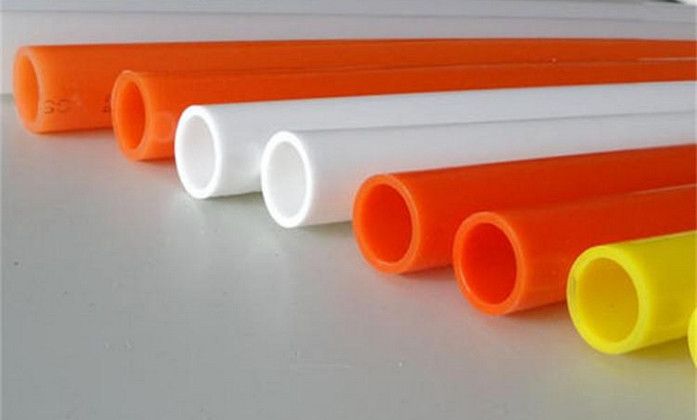

PE-RT Pipe is also called heat-resistant Polyethylene Pipe. It includes PE-RT ⅠAnd PE-RT Ⅱ Pipes. Read this article to know what are they, their applications & features, and so on.

PE-RT Pipe

PE-RT Pipe is also called heat-resistant Polyethylene Pipe. The main raw material used for heat-resistant polyethylene (PE-RT) pipes and fittings is ethylene-octene (or hexene, butene) copolym. It is selected by selecting octene (or hexene, butene) as a comonomer.

In the polymerization reaction, the number and distribution of the branches on the polyethylene molecular chain are appropriately controlled to make it have heat-resistant properties. Compared with ordinary PE pipes, it not only retains the hot melt connection of the original PE pipe, but also the advantages of sanitation, non-toxicity, low temperature resistance and good flexibility.

At the same time it makes up for its shortcomings of inability to withstand high temperatures. It is the economical pipes of current floor heating pipes, because of they are resistant to high temperatures, Long-life and easy-to-construct.

Application

- Low-temperature radiant heating system (floor heating, wall radiant heating, roof radiant heating).

- Large-scale stadium, parking lot, highway snow melting pipeline system.

- Building cold and hot water supply pipe network system.

- Sanitary water piping system.

- Central air-conditioning pipe network system.

- Refrigeration piping system for large skating rink.

Features

- Good thermal stability and long-term pressure resistance, which can be used safely for 50 years

- Excellent temperature resistance. The use temperature range is -70℃~90℃

- High impact resistance. It is suitable for winter construction

- Excellent heat dissipation performance, high thermal conductivity and good heat transfer effect

- Light weight, good flexibility, coil supply

- Hot-melt connection can be made with pipe fittings of the same material. It's easy to install, connect reliably and maintain conveniently.

- Non-toxic and tasteless, which is meeting drinking water sanitation requirements.

- Recyclable and environmentally friendly.

Executive Standard

- GB/T 28799.1-2012 "Heat-resistant Polyethylene (PE-RT) Piping System for Hot and Cold Water-Part 1: General Provisions"

- GB/T 28799.2-2012 "Heat-resistant polyethylene (PE-RT) piping system for hot and cold water-Part 2: Pipes"

- GB/T 28799.3-2012 "Heat-resistant Polyethylene (PE-RT) Piping System for Hot and Cold Water-Part 3: Pipe Fittings"

PE-RT Ⅱ Pipes

The PE-RTⅡ pipe is a heat-resistant high-density polyethylene pipe. It not only inherits the PE-RTⅠ pipe with hygienic, non-toxic, low temperature resistance, good flexibility, but also greatly improved heat resistance, compressive strength, physical and chemical properties.

This makes it more suitable for the hot and cold water area in the building.

| Property | Unit | Test Value | |

|---|---|---|---|

| PE-RTⅠ | PE-RTⅡ | ||

| Density(23℃) | g/cm³ | 0.937 | 0.947 |

| Tensile yield stress(23℃) | Mpa | 18.3 | 22 |

| Tensile elongation at break | % | 700 | 800 |

| Shore Hardness | - | 50 | 60 |

| Maximum use temperature | ℃ | 70 | 90 |

Advantages of PE-RT Ⅱ

- PE-RT Ⅱ pipe has higher tensile strength and better stability for long-distance laying.

- PE-RT Ⅱ pipe has better surface hardness and can better deal with scratches during construction and use.

- Under the same nominal outer diameter, PE-RT Ⅱ has a higher S value than PE-RTⅠ . It is with thinner wall thickness and larger circulation than PE-RTⅠ.

- With high heat-resistant temperature. It can be used in industrial and civil hot water pipe network systems.

- PE-RTⅡ has stronger creep resistance and higher rigidity than type PE-RTⅠ.

The Welding Processes

PE-RT Pipe Hot Melt Socket Welding Process

In the PE-RT pipe hot melt socket welding process, there are two important points must be noted.

-

The temperature of the hot melt machine is controlled at 250-260°C;

-

PE-RT pipes and fittings should stay in the die for a short time and fast when they are inserted.

When the pipes and fittings are pulled out again, the pipes and fittings should be inserted quickly at that moment. The normal operation process is to adjust the machine to 255°C and prepare the PE-RT pipe fittings to be hot-melted. When the temperature of the hot-melting machine reaches the set temperature, hold the pipe with the left hand and the right hand with the pipe fittings to balance and insert until the left and right hands. At the same time, when you feel that the pipe fitting has reached the socket depth, quickly pull the pipe fitting out of the die. And quickly insert the pipe into the pipe fitting for a certain period of time to cool down before letting go.

PE-RT Pipe Hot Melt Butt Welding Process

- Fix the parts that need to be butted. Fix the PE-RT pipes and components to be welded on the fixture of the welding machine. The center lines of the fixed pipes and components should be on the same level. And the pipe walls should overlap, avoiding heights, lows, left and right stagger.

- Flatten the end of PE-RT pipe. Before milling, use a clean cotton cloth to wipe clean the inside and outside of the pipe end within 100mm. Then fix the milling cutter and push the running part to mill the pipe end. There are two issues to pay attention to here. One is to slowly withdraw the force before stopping to ensure that the pipe end is smooth (a sudden withdrawal of the force will leave a groove shell on the pipe end). The other one is to prevent secondary pollution of the pipe end before heating.

- Hot melt butt joint Before the heating plate melts the butt surface, check the matching situation again. If there are visible gaps or wrong joints, they must be corrected by adjusting the tightening nut. First, preheat the heating plate of the hot melt butt welder to 210 ~ 220℃, and then melt the end surface of the PE-RT pipe. The melting time is generally wall thickness × 10 seconds. It should be noted here that the temperature indication of the heating plate can only be used as a reference. The indication may sometimes differ from the actual situation due to environmental temperature and its own quality. The hot melt meets the design requirements and mainly depends on the melting and crimping of the pipe end. The crimping thickness shall not be less than 1/10 of the pipe wall thickness. And the standard must be met when the two ends are completely fused together.

- After the two hot-melt surfaces (PE-RT pipe and pe-rt pipe or PE-RT pipe and PE-RT pipe fittings) meet the welding requirements, quickly remove the heating plate and apply force to both ends Into one. After the force is applied, the lock should be locked immediately to maintain a constant butt pressure at the interface. The pressure cannot be released until the temperature of the interface drops to the ambient temperature, and the fixing device can be removed. In this step, please note that the pipe cannot be moved during the cooling process. No external force can act on the pipe.

- After fixing the machine device, check the appearance of the fusion joint. The height and width of the hot fusion ring of the joint should be uniform and beautiful. Its height is 2

4 mm, and the width is 48 mm.