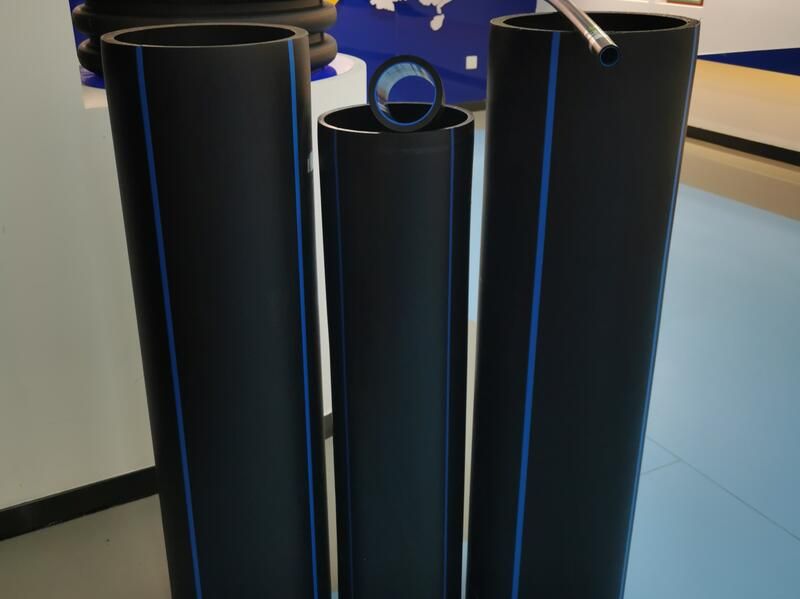

PE mine pipe is made of PE resin as the main raw material, adding appropriate amount of additives, and extruded at high temperature. Its performance not only has the characteristics of ordinary PE pipe, but also has its own characteristics: anti-static and flame retardant.

Introduction

Performance of Raw Materials: High performance superconducting carbon black is used as anti-static agent, and PBDEs and antimony trioxy3 are used as flame retardant, then fully mixed, plasticized and pelletized. The physical and mechanical properties of gas pipes produced with this special material can meet the pe-80 water supply pipe standard, and the anti-static and flame retardant properties meet the requirements of mt558.1-2005 of the Ministry of coal.

PE Mining Pipe Features

1.Anti-static, Flame Retardant The anti-static and flame retardant components of PE mining pipe are evenly distributed in the pipe body, so the anti-static and flame retardant performance indicators will not be affected even if the time is long.

2.Light Weight, Easy Installation The density of PE mining pipe is small, the unit weight is only one third of the steel pipe, so PE mining pipe is not only convenient for transportation and installation, but also can reduce the labor intensity of workers, so as to improve the work efficiency.

3.Corrosion Resistance, No Scaling PE mine pipe has strong corrosion resistance and non scaling, especially suitable for underground transportation of high sulfur water and water containing calcium and magnesium ions. The cost of pipeline anti-corrosion and descaling can be greatly saved.

4.Self Lubricity The inner wall of polyethylene pipe used in coal mine is smooth, the resistance of conveying fluid is small, and the roughness is far less than that of steel pipe and FRP pipe. Under the same conditions, the conveying capacity can be increased by 30%. Good flexibility and strong resistance to geological settlement.

5. Anti-aging, Fast Cracking Resistance Coal Mine polyethylene pipe aging resistance is good, low temperature is not easy to embrittlement, fast cracking resistance; It has good toughness and can effectively absorb impact energy; The bending modulus is moderate and the elongation at break is more than 400%. In the coal mine, geological subsidence and other phenomena occur from time to time under the special working conditions, the polyethylene pipe used in coal mine can effectively avoid the fracture accident compared with the traditional rigid steel pipe and glass steel pipe.

6.Good Wear Resistance The comparative test of the wear resistance of polyethylene pipe and steel pipe used in coal mine shows that the wear resistance of polyethylene pipe used in coal mine is 4 times that of steel pipe. In the field of coal transportation, compared with steel pipe, polyethylene pipe for coal mine has better wear resistance, which means that polyethylene pipe for coal mine has longer service life and better economy.

7.Impact Resistance Low temperature embrittlement temperature of polyethylene is very low, which can be used at lower temperature.

8.High Toughness Elongation at break generally exceeds 500%.

9.Good Flexibility The pipeline can be bent, which can be used to dredge the pipeline at sea and reduce the rubber soft knot.

10.Easy Connection Hot melt connection, pipe clamp connection or flange connection are adopted for convenient construction.

Application Scope of PE Pipe for Coal Mine

It is widely used in underground water supply and drainage pipe, mine positive pressure ventilation pipe, mine negative pressure ventilation pipe, mine shotcrete pipe and mine gas drainage pipe.

Connection of PE Mining Pipe

- Hot melt butt joint: special butt welding machine is mainly used to connect pipes

- Steel plastic connection: flange, thread thread and other methods can be used for connection.

- Socket connection: special socket connection is mainly used.

Transportation and Storage of PE Mine Pipe

During the transportation of pipes, severe impact and throwing should be avoided as far as possible. Buried PE leakage pipes are strictly prohibited to be dragged and scraped, and the scratch of sharp and hard objects, as well as the pollution of oil and chemicals should be prevented.

PE mining pipes should be stored as far away from heat source, oil and chemical pollution as possible. The ground should be flat and well ventilated in the warehouse. If they are stacked outdoors, they should be covered. The pipes should be stacked horizontally and neatly, and the stacking height should not exceed 1.5m.

Industry Standard Requirements of PE Mining Pipe

- Appearance: The inner and outer walls of PE mining pipe shall be smooth, flat, free of bubbles, cracks, obvious grooves and depressions, etc., and the appearance color shall be uniform. The two ends of each pipe shall be perpendicular to the axis.

- Wall Thickness Deviation: The deviation of wall thickness of the same section of pipe shall not exceed 14%.

- Wall Thickness: The minimum wall thickness of pipe corresponding to nominal outer diameter and nominal pressure shall meet the standard requirements.

- Non Roundness: The non roundness of the pipe shall not be greater than 5%.

- Flat: PE mining pipe is pressed to the inner wall and full, and there shall be no crack and damage.

- Hydraulic Pressure: PE pipe shall be free of leakage and damage when the test pressure is kept for 100h.

- Tensile Strength and Elongation at Break: The position elongation shall not be less than 9.0MPa and the elongation at break shall not be less than 300%.

- Surface Resistance: According to the different use of PE mining pipe, the surface resistance requirements are different.

(1) Pipe for water supply and drainage: the arithmetic average value of surface resistance of outer wall shall not be greater than 1.0109Ω; (2) Positive pressure air duct: the arithmetic average value of the surface resistance of inner and outer walls shall not be greater than 1.0108Ω; (3) Pipe for grouting: the arithmetic average value of surface resistance of inner and outer walls shall not be greater than 1.0108Ω; (4) Negative pressure air duct: the arithmetic average value of the surface resistance of inner and outer walls shall not be greater than 1.0106Ω; (5) Gas drainage pipe: the arithmetic average value of the surface resistance of the inner and outer walls shall not be greater than 1.0*106Ω.

- The flange used in coal mine shall be greater than or equal to all technical standards of PE mine pipe.