PE heat shrinkable tape is Polyethylene heat shrinkable tape. It is made of irradiated cross-linked EPR rubber. It is suitable for steel pipe anti-corrosion projects to prevent steel pipe oxidation and quick repair of various cable sheath damages. It can resist ultraviolet rays. It does not need to use fire to heat; it can provide reliable waterproof insulation protection for pipelines in places where fire sources cannot be used.

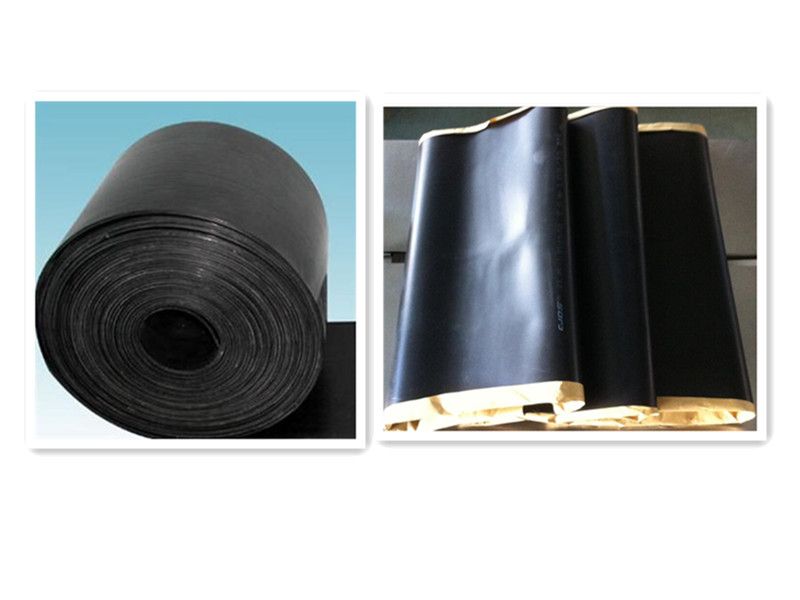

The heat-shrinkable tape is designed for the anti-corrosion of welded joints of buried and overhead steel pipes and the heat-preservation mending of heat-insulating pipes. It is composed of a heat shrinkable layer base material and a hot melt adhesive. The hot melt adhesive can form a good bond with the heat shrinkable layer base material, the surface of the steel pipe and the solid epoxy coating.

The heat-shrinkable tape is called a looper in the industry, which is relative to the heat-shrinkable sleeve. That is, the width of the heat-shrinkable tape itself is the same as the width of the patch, and then a layer is wound around the patch, and then the two ends are connected.

The heat shrinkable sleeve can only be used for pipes with matching pipe diameters, and the heat shrinkable tape can be used for pipes of various pipe diameters, that is, when in use, the heat shrinkable tape can be wound around the pipe to match the pipe, so the heat The shrink tape has high flexibility in use. In addition to the main body of the heat shrink tape, it is also equipped with rubber strips and fixing sheets. The heat shrink tape is convenient for large-scale production and construction.

Steel pipe anticorrosive heat-shrinkable tape is a new type of anticorrosive material for steel pipe welds with good performance and easy operation. It is composed of a double-layer material of a base material and a hot melt adhesive layer. The base material is a plastic sleeve (sheet) formed by extrusion, radiation crosslinking, and stretching of polyethylene raw materials. Hot melt adhesive is a kind of special adhesive. It is solid at room temperature. It can flow in a molten state when heated, can be coated on the substrate, and has good adhesion to metals and plastics.

The outer anti-corrosion layer of the steel pipe is usually a three-layer structure (also called three-layer PE anti-corrosion), the anti-corrosion paint primer is in contact with the steel pipe, the middle is hot melt adhesive, and the outermost layer is cross-linked polyethylene. In a few cases, the outer anti-corrosion layer of the steel pipe is also adopted as a two-layer (two-layer PE anti-corrosion). The sealing hot melt adhesive is used to contact the steel pipe, and the outer layer is cross-linked polyethylene. The anti-corrosion of jacket is composed of foam jacket (inner layer), hot melt adhesive (middle layer) and base material (outer layer).

For technical requirements, see Oil and Gas Industry Standard SY/T0413-2002 "Technical Standards for Polyethylene Anti-corrosion Coatings for Buried Steel Pipelines" SY/T4054-2003 Radiation Cross-linked Polyethylene Heat Shrinkable Tape (Set)", SY/T0415-1996 "Buried Technical Standard for Rigid Polyurethane Foam Anti-corrosion and Thermal Insulation Layer of Ground Steel Pipeline".

Product Features: high adhesion; excellent sealing and waterproof; excellent voltage resistance; weather resistance, aging resistance, chemical corrosion resistance, mildew resistance; good elasticity, excellent plasticity; bending resistance; low temperature mobile operation; easy and flexible to use.

How to use: Pull the elliptical circle on the surface into a circle, and wrap it around 1/2 of the circle.

Requirements of PE heat shrinkable tape for anti-corrosion of oil and gas pipeline

1. General requirements for steel pipe patching construction

Before patching, the patching part must be cleaned. The burr, welding slag, dirt, oil and other sundries near the circumferential weld must be cleaned. Derusting treatment shall be carried out on the surface of patching part, and the quality of surface derusting treatment shall reach sa2.5-sa3.0 specified in "rust grade and derusting grade of steel surface before painting" GB / 8923. Sand blasting or electric tools can be used to remove rust. The polyethylene layer at the lap joint shall be ground to rough surface. Groove treatment shall be carried out at the end and groove treatment shall be carried out at the end of the slope angle. The slope angle shall not be greater than 30 degrees. Then, the flame heater shall be used to preheat the patching part. The lap width between anticorrosive polyethylene heat shrinkable tape and polyethylene anticorrosive coating shall not be less than 100 mm. If the humidity is more than 85% or in rainy or snowy days, the construction shall be stopped.

2. Quality inspection after construction

The quality inspection of anti-corrosion polyethylene heat shrinkable tape or winding tape shall check the appearance of patching one by one. The surface of anti-corrosion polyethylene heat shrinkable tape or winding tape shall be smooth and flat without wrinkles and bubbles. The slope corners at both ends shall be closely connected with the heat shrinkable sleeve without voids. There shall be no carbonization on the surface. There should be hot melt adhesive overflowing evenly around the PE heat shrinkable tape. A spark leak detector is used to inspect the pinholes one by one at the joint patching. The leak detection voltage is 15kV. In case of pinhole, it should be re patched. The adhesive force of anti-corrosion polyethylene heat shrinkable tape shall meet the requirements. The peel strength of anti-corrosion polyethylene heat shrinkable tape shall not be less than 50N / cm when the temperature of pipe body is about 25 ℃.

Quality inspection of anti-corrosive coating (primer) The quality of anti-corrosion coating (primer) is mainly leak detection. When the coating is fully cured and cooled to the ambient temperature, each patch is detected. The test voltage is 2KV for ordinary level and 2.5KV for reinforced level. When the test head contacts the coating, it moves at a speed of about 0.2m/s.