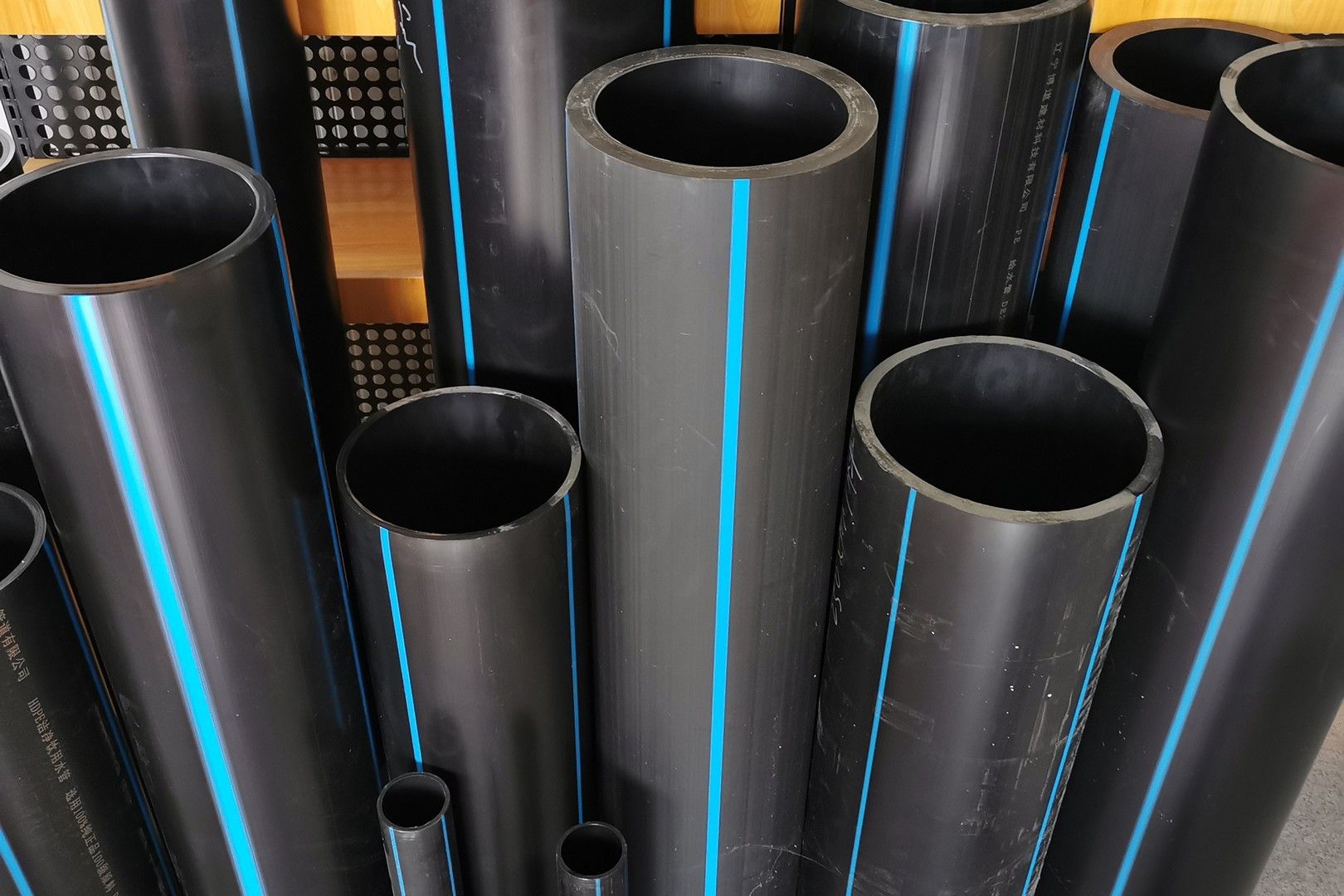

In our daily lives, we will come into contact with HDPE and PE pipe, but I think most of us don’t know the difference of them. Here I will explain their differences in the following aspects.

The Material

HDPE(high-density polyethylene plastic) is called as "High Density Polyethylene" or "HDPE" for short. HDPE is a highly crystalline, non-polar thermoplastic resin. The appearance of the original HDPE is milky white and the thin section is translucent to a certain extent.

PE(polyethylene plastic) is the most basic kind of plastic. Plastic bags and cling film are all PE. HDPE pipe is a high-density polyethylene pipe. HDPE double-wall corrugated pipe is common HDPE pipe. PE pipe is a general polyethylene pipe. PE water supply pipe is a common PE pipe.

The Types of PE Pipe

PE pipe can be divided into low density polyethylene pipe(LDPE), medium density polyethylene pipe(MDPE) and high density polyethylene pipe(HDPE).

LDPE

What is LDPE?

Low density polyethylene is also known as high pressure polyethylene (LDPE). It is the lightest variety of polyethylene resin. It is milky white, tasteless, odorless, non-toxic, and glossless wax like particles. It has good softness, extensibility, electrical insulation, and transparency. It’s also easy processing and certain air permeability. LDPE has good chemical stability, alkali resistance and general organic solvent resistance.

The Main Characteristics

- The film is microemulsion white, transparent and soft. The strength is lower and the impact strength is higher than HDPE.

- Cold resistant, low temperature resistant and high temperature resistant. The thicker film can withstand the sterilization process of 90 ℃ hot water immersion.

- Good moisture resistance, stable chemical properties, insoluble in general solvents.

- The storage period of its contents should not be too long when it is used as a food package which is easy to oxidize.

- Oil resistance is poor, products can be slowly dissolved up. When packaging greasy food, it will make the food have a harrass taste after long storage.

- Long term exposure to UV and heat will cause aging, which will affect its physical and dielectric properties.

- The melting point is 110 ~ 115 ℃ and the processing temperature is 150 ~ 210 ℃. If it is in inert gas, the temperature can reach 300 ℃ and it is still stable. However, it is easy to degrade when the melt contacts with oxygen.

The Application

The low-density polyethylene (high-pressure polyethylene) referred to in the petroleum industry is a plastic material, which is suitable for various molding processes of thermoplastic molding processing.

The molding processability is good, such as injection molding, extrusion molding, blow molding, rotational molding, Coating, foaming process, thermoforming, hot air welding, thermal welding, etc.

LDPE is mainly used as film products. Such as:

- Agricultural film: floor covering film, agricultural film, vegetable greenhouse film, etc.,

- Packaging film: candy, vegetables, frozen food, etc.,

- Blown film for liquid packaging: milk, soy sauce, juice, Tofu, soy milk, etc.,

- Heavy Packaging Bags: shrink packaging films, elastic films, lining films, ETC.,

- Construction films: general industrial packaging films and food bags, etc. In injection Molded Products: small containers, lids, daily-use products, plastic flowers, and injection-stretch-blow-molded containers.

- Medical Appliances: pharmaceutical and food packaging materials, extruded pipes, plates, wire and cable coating, profiled materials, thermoforming and other products;

- Blow-molded hollow molded products: food containers such as dairy products and jams, drugs, cosmetics, and chemicals Product containers, tanks, etc.,

LDPE is suitable for making films, heavy packaging films, cable insulation materials, blow molding and foaming products.

MDPE

What is MDPE?

MDPE is medium density polyethylene. It is synthesized by copolymerization of α - olefin and density control.

The Characteristic and Parameters

The characteristic of MDPE is Environmental stress crack resistance and long-term strength retention. The parameters of MDPE is as table.

| Character | Parameter |

|---|---|

| Relative Density | 0.926-0.953 |

| Crystallinity | 70%-80% |

| Average Molecular Weight | 200,000 |

| Tensile Strength | 8-24 MPa |

| Elongation at Break | 50%-60% |

| Temperature | 126-135°C |

| Melt Flow Rate | 0.1-35 g/10 minutes |

| Heat Distortion Temperature (0.46 MPa) | 49-74°C |

The Application

MDPE can be processed by extrusion, injection, blow molding, rotomolding, rotation and powder molding. The production process parameters are similar to the HDPE and LDPE. It’s commonly used in pipes, films, hollow containers, etc. MDPE is used for high-speed molding of various bottles, high-speed automatic packaging films, various injection products, rotational molding products, wire and cable coatings, waterproof materials, water pipes, gas pipes, etc.

HDPE

What is HDPE?

HDPE is an opaque white waxy material that specific gravity is lighter than water(0.941~0.960). It is soft and tough, but slightly harder than LDPE. It is also slightly elongated, non-toxic, tasteless.

The Characteristics

- HDPE has good heat resistance and cold resistance, good chemical stability, high rigidity and toughness and good mechanical strength.

- Dielectric properties and environmental stress cracking resistance are also good.

- The hardness, tensile strength and creep are better than those of LDPE.

- Wear resistance, electrical insulation, toughness and cold resistance are good, but slightly worse than low density insulation.

- Good chemical stability, at room temperature, insoluble in any organic solvent, resistant to acid, alkali and various salt corrosion.

- The membrane has low permeability to water vapor and air and low water absorption.

- The aging resistance is poor, and the environmental cracking resistance is not as good as that of LDPE, especially the thermal oxidation will reduce its performance. Therefore, antioxidant and ultraviolet absorbent should be added to improve the resin.

- The hot deformation temperature of HDPE film under stress is lower, which should be paid attention to in application.

The Application

HDPE resin can be molded into plastic products by injection, extrusion, blow molding and rotary molding.

- Injection Molding Products: Various types of containers, industrial accessories, medical supplies, toys, shells, corks and shields, etc.,

- Extrusion Molding Products: pipes, stretch strips, strapping belts, monofilament, wire and cable sheath, etc.

- Blow Molding Products: Various kinds of hollow containers and ultra-thin films. In addition, it can also form building decorative panels, shutters, synthetic wood, synthetic paper, synthetic film and calcium plastic products.

HDPE can form so many products, so the function and application is broad. It can be used in food industry, pharmaceutical industry, construction industry, agriculture, mining, etc.,

When you understand LDPE, MDPE and HDPE, do you know the difference between them HDPE and PE pipe? In a word, HDPE pipe is one type of PE pipes.