PE mining pipe is a kind of pipe with wear resistance in the forefront of some engineering plastics. The higher the molecular weight of other materials, the more wear-resistant they will be, even more than many metal materials. Under the conditions of strong corrosion and high wear, the service life is 4-6 times that of steel pipe and 9 times that of ordinary polyethylene; And improve the conveying efficiency by 20%. The service life of PE mining pipe underground can exceed 20 years, with obvious economic benefits, impact resistance, wear resistance and double resistance effect.

Characteristics of PE Mining Pipe Special Raw Materials

PE mining pipe special raw materials not only have excellent long-term compressive strength, but also have excellent resistance to slow stress cracking growth and fast stress propagation. He3490-ls is a special material for black PE100 pipe. It also has excellent anti suspension performance.

The Specifications of PE Mining Pipe(Unit: mm)

φ 20、 φ 25、 φ 32、 φ 40、 φ 50、 φ 63、 φ 75、 φ 90、 φ 110、 φ 125、 φ 140、 φ 160、 φ 180、 φ 200、 φ 225、 φ 250、 φ 280、 φ 315、 φ 355、 φ 400、 φ 450、 φ 500、 φ 560、 φ 630、 φ 710、 φ 800、 φ 900、 φ 1000.

Polyethylene Pipe for Underground Coal Mine

PE mining pipe takes polyethylene resin as the main raw material, adds an appropriate amount of additives and is extruded at high temperature. Its performance not only has the characteristics of general polyethylene pipe, but also has its own characteristics: antistatic and flame retardant.

PE Mining Pipe Type for for Underground Coal Mine

- Polyethylene water supply and drainage pipe (KS) for underground coal mine.

- Polyethylene shotcrete pipe for underground coal mine (kJ).

- Polyethylene positive pressure ventilation pipe (KFZ) and negative pressure ventilation pipe (KFF) for underground coal mine.

- Polyethylene gas drainage pipe for underground coal mine (kw).

- Polyethylene general purpose pipe (km) for underground coal mine: suitable for gas drainage, water supply and drainage, positive pressure ventilation, negative pressure ventilation and slurry spraying.

Application Scope of PE Pipe for Coal Mine

It is widely used in underground water supply and drainage pipe, mining positive pressure ventilation pipe, mining negative pressure ventilation pipe, mining shotcrete pipe and mining gas drainage pipe.

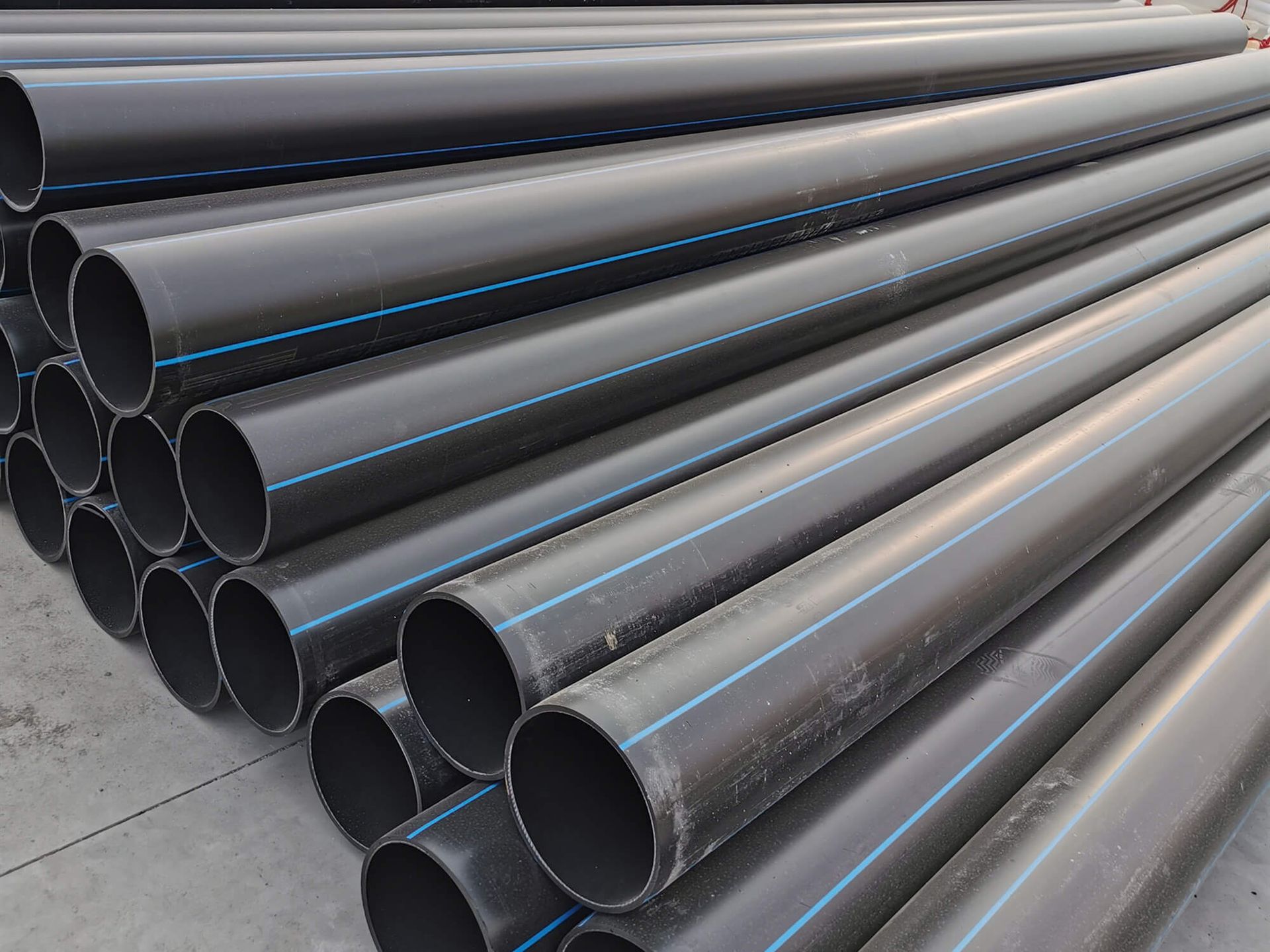

PE Mining Pipe Appearance

(1) Pipe color: Black

(2) The inner and outer walls of the pipe shall be smooth and flat without bubbles, cracks, obvious grooves and depressions, and the appearance color shall be uniform.

(3)Both ends of each pipe shall be perpendicular to the axis.

Excellent Quality

- The antistatic agent and flame retardant of the pipe are evenly distributed in the polyethylene resin body, and the antistatic and flame retardant indexes will not be affected by long service time.

- Low pipe density (1 / 8 of steel pipe and 1 / 2 of FRP pipe), light weight, easy handling without machinery, greatly reducing labor intensity, fast installation and shortening construction cycle.

- The pipe is corrosion-resistant and not easy to scale. It is especially suitable for underground transportation of media containing sulfur, calcium and magnesium ions, saving the cost of anti-corrosion and descaling, and its service life is much longer than that of other pipes.

- The inner wall of the pipe is smooth (the absolute roughness K value of the inner wall is 1 / 6 of that of the steel pipe), and the hydraulic characteristics are excellent. Under the same pipe diameter, the conveying capacity can be increased by 25% compared with the metal pipe.

- It has high strength, impact resistance, excellent mechanical properties, good aging resistance, hard to embrittlement, toughness, absorbs impact energy, and breakage elongation can reach 200%.

- Good water tightness and environmental protection. The pipes are well combined and easy to construct. The raw material is PE resin, with good hygienic performance, no pollution, no harm to workers, green environmental protection and cleanness.

Connection Mode of PE Mining Pipe

- Hot melt butt joint: the hot melt butt joint mainly uses a special butt welding machine to connect the pipes.

- Steel plastic connection: flange, screw thread and other methods can be used for connection.

- Socket connection: it is mainly connected by special socket.

How to Transport and Store PE Mining Pipe?

Transportation

During the transportation of pipes, violent impact and throwing shall be avoided as far as possible. For buried PE leakage pipes, it is strictly prohibited to drag and wipe and prevent the scratch of sharp hard objects, as well as the pollution of oil and chemicals.

Storage

PE mining pipes shall be stored as far away from heat sources, oil pollution and chemical pollution as possible. The ground shall be flat and in a warehouse with good ventilation. If they are stacked outdoors, there shall be covers. The pipes shall be stacked horizontally and neatly, and the stacking height shall not exceed 1.5m.

Our Manufacturing Technology of PE Mining Pipe

Combined with the actual environment, the mining pipe is determined according to the engineering conditions, environmental characteristics, types, mining pipe and other factors of the mine, the requirements of operation reliability and convenient maintenance, and the principle of fairness of economic capacity.

Among all engineering plastics, HDPE mining pipe has the highest wear resistance among plastics. The higher the molecular weight, the more wear-resistant the material is, even more than many metal materials (such as carbon steel, stainless steel, bronze, etc.). Under the condition of strong corrosion and high wear, the service life is 4-6 times that of steel pipe and 9 times that of ordinary polyethylene; Moreover, the conveying efficiency is improved by 20%. The flame retardant and antistatic properties are good, which meet the standard requirements. The downhole service life is more than 20 years, with remarkable economic benefits, impact resistance, wear resistance and double resistance. If you are finding PE pipe manufacturer, please contact us to get a help.