Studies have shown that the groundwater infiltration rate of new reinforced concrete pipes is 210m³/(km·d), which accounts for 19.4% of the urban sewage volume served by these pipes. Urban drainage pipes with high groundwater levels have a large amount of groundwater infiltration. The higher the groundwater level above the bottom of the new reinforced concrete drainage pipe, the greater the amount of groundwater infiltration into the drainage pipe.

In addition, with the extension of the pipeline's use time, due to various damage factors, the nozzle will crack and even the pipeline or auxiliary structures will be destroyed, and the amount of infiltration will inevitably increase significantly. 24 overseas cities have conducted actual measurements on old drainage pipes with a diameter of 150-980mm, and the groundwater infiltration rate is 4.2-3100m³/(km·d).

The infiltration of groundwater into the drainage pipeline will increase the amount of sewage that is transported, lifted and treated, resulting in higher investment and operating costs for drainage projects. Therefore, under economically feasible conditions, the amount of groundwater infiltration into drainage pipes should be reduced as much as possible.

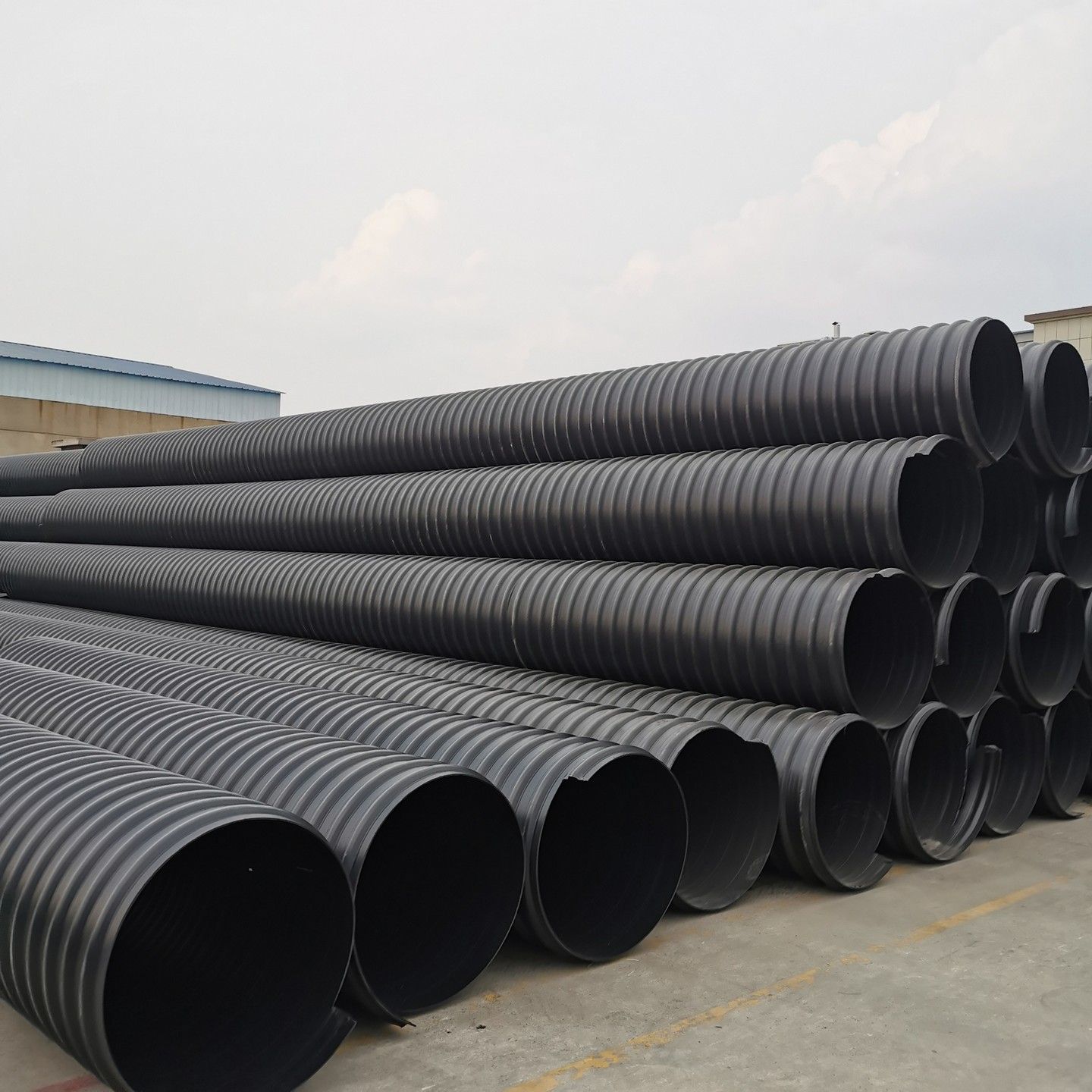

PE Sewage Pipe Anti-seepage Method

1. Control the Quality of Pipes

In the selection of pipes, all pipes and their accessories must meet the design drawings and the product material requirements specified by the country. It is required that the factory product qualification certificate and related materials of the pipe are complete, and can be used only after passing the inspection. Before the pipeline is transported and after it is transported to the site, the pipelines should be checked and accepted one by one according to the standards.

To inspect the inner surface, outer surface and joints of pipes and pipe fittings, the quality should meet the requirements, and there should be no signs of damage. The appearance of the rubber ring should be free of bubbles, cracks, wrinkles and deformation. Avoid contact with chloroform and aromatic solvents during storage. Pipes and fittings found to have quality problems should be returned.

Anti-leakage of pipe joints At present, both reinforced concrete pipes and plastic pipes can adopt flexible joints. Reducing the leakage of the flexible interface pipeline can be considered from the selection of the interface rubber ring, the application of the rubber strip, and the improvement of the impermeable sealing quality of the rubber ring.

2. The Selection of Rubber Ring

At present, the commonly used rubber rings for pipelines include rolling rubber rings and sliding rubber rings. Commonly used rolling rubber rings are rubber rings with an O-shaped cross-section.

However, it is easy to roll at the socket end when it is installed, and it is easy to be twisted, which affects the sealing performance of the interface. A wedge-shaped rubber ring with a cross section similar to a triangle is commonly used for sliding rubber rings.

The manufacturing process of the sliding rubber ring is more complicated and the price is higher. In practical applications, sometimes due to insufficient elasticity, the sealing effect is not good. But overall, the use effect of sliding rubber ring is better than rolling rubber ring, it should be preferred.

3. The Application of Rubber Strips

The rubber strip will expand in volume when it meets with water. Compared with the ordinary rubber ring, it can touch more irregular surfaces and gaps at the joint of the concrete pipe, and it has a stronger anti-leakage ability. But the price is more than twice that of the general rubber ring. In addition, compared with conventional rubber waterstops in terms of heat resistance, tensile strength, brittleness temperature, etc., there is a certain gap in performance. Prevent damage to the pipeline due to the foundation of the pipeline.