PE has a variety of different drainage pipes. The useful of them is different, but the function is the same - Drain Water. The installation of the drainage pipe is of great significance, because with it, the situation of flooding will not occur. So what types of PE drainage pipes are there? The following we will recommend 4 common PE drainage pipes to you.

At present, there are many varieties of PE drainage pipes, mainly including: HDPE double-wall corrugated pipe, PE hollow-wall winding pipe, HDPE steel belt reinforced polyethylene spiral corrugated pipe and plastic steel winding pipe. Due to different uses, their specifications are also different.

HDPE Double Wall Corrugated Pipe

Double-wall corrugated pipe is a new type of lightweight pipe made of high-density polyethylene. It has the characteristics of light weight, high pressure resistance, good toughness, fast construction and long life. Its excellent pipe wall structure design is compatible with other structures. Compared with other pipes, the cost is greatly reduced. And because the connection is convenient and reliable, it is widely used.

Features:

- Unique product structure and strong resistance to pressure.

- The inner wall is smooth and the excess flow is large.

- The product is easy to connect, the interface is well sealed, corrosion resistance, zero leakage, no scaling, and avoid secondary pollution. It is an ideal "green pipe".

- The product has good flexural properties and can adapt to uneven settlement of the soil.

- Long service life, buried in the ground for more than 50 years.

- The product is light in weight and convenient in construction, which can reduce construction costs and shorten the construction period.

- At a speed of 15 feet per second, the wear resistance is 3 to 5 times higher than that of ordinary or fine-grained steel pipes.

Application Field

- Municipal drainage and sewage pipe system engineering.

- Buried underground drainage and sewage in apartments and residential communities.

- Pre-buried pipelines on expressways, and seepage water pipe networks in golf courses.

- Water conservancy projects such as irrigation and drainage of farmland water conservancy and waterlogging drainage.

- Used in the transportation and ventilation of fluids in chemicals and mines.

- Protective sleeves for underground pipelines and communication cables, etc.

PE Hollow Wall Winding Pipe

Hollow-wall wound pipe is a kind of pipe made of high-density polyethylene (HDPE) and formed by winding and welding. Due to its unique forming process, it can produce pipes with a diameter of up to 3 meters, which is difficult to complete by other production processes. Its excellent welding performance not only guarantees the product molding process and product quality, but also provides a variety of reliable methods for construction connection. At the same time, this is also an important reason why leakage rarely occurs. This is also mask it has the unique environmental protection function that other pipes do not have. It provides a very effective method for pollution prevention and control that people are currently concerned about.

Features:

- Strong impact resistance and pressure resistance. The pipe wall adopts a unique I-shaped structure. It's with large elastic deformation and not easy to damage. And it has good applicability to any base.

- Anti-aging. The pipe can withstand direct sunlight during storage and construction, and the material attenuation in 50 years is fully considered in the pipe design and production process.

- Wide applicable temperature range. It can be used in the temperature range of -50℃ to 60℃.

- Light weight. The weight is 1/10 of the weight of the cement pipe (under the same water delivery efficiency). No large construction equipment is required.

- Easy to connect.

- Superior wear resistance. It's more wear-resistant than cement pipes and steel pipes and with a service life of more than 50 years.

- The price of raw materials is low. And the cost of construction, management and maintenance is low.

- HDPE is a non-toxic material. It's harmless to the land, recyclable and an environmentally friendly green product.

- Stable chemical performance. Strong acid, alkali & salt resistance, corrosion resistance of sewage, wastewater and chemicals, corrosion resistance of decay in the soil, no rust.

Application Field

It's suitable for conveying water temperature below 45℃ to drain water, including:

- Municipal Drainage

- Building Outdoor Drainage,

- Buried Farmland Drainage and Drainage,

- Industrial Sewage,

- Road Drainage & Sewage Treatment Plant

- Sports Field Plaza Project Drainage and Electrical & Telecommunications Projects, etc.

Executive Standard

| Item | Index |

|---|---|

| Exterior | Inner surface is smooth, outer surface is flat, and the spiral hollow pipe is buried in the pipe wall. |

| Nomina Inner Diameter (mm) | 150-3000 |

| Nominal Length (mm) | 6000, Custom |

| Ring Stiffness (KN/m^2) | ≧2, ≧4, ≧6.3, ≧8, ≧12.5, ≧16 |

| Impact Performance (TIR)/% | ≦10 |

| Ring Flexibility | No Delamination, No Fracture, No Buckling Deformation |

| Variable Ratio | ≦4 |

| Tensile Strength of Seam/N (DN/ID 2800) | 1020 |

| Longitudinal Retraction Rate | ≦3%, The pipe should be free of delamination and cracking |

| Oven Test | There should be no delamination or cracking at the welded joint of the pipe |

|

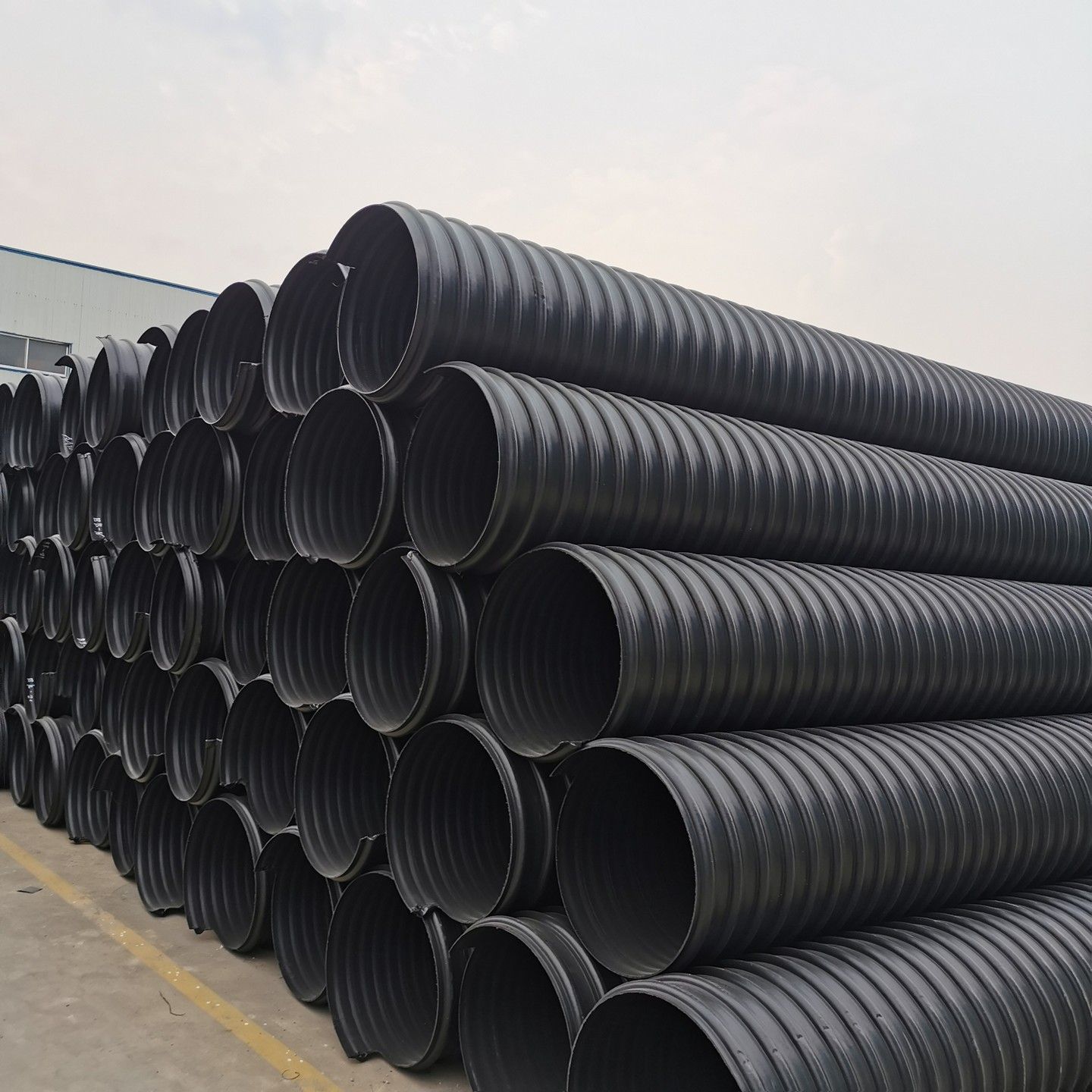

HDPE Steel Belt Reinforced Spiral Corrugated Pipe

It uses U-shaped steel strip composite PE material that greatly increase the ring stiffness of the pipe without increasing the cost. And the strength of the pipe is greatly improved compared with the winding pipe and the carat pipe under the same weight. It can solve a series of problems such as heavy load. The advantages of large-diameter pipes are more obvious. The pipe diameters are from DN300mm to DN2400mm, and the ring stiffness is maintained above 8KN/m2, which is lighter and stronger than cement pipes and other plastic pipes.

Features

- Chemical Resistance: not corroded by pollution, waste water and chemicals, and not corroded by rotten substances in the soil.

- Impact Resistance: The pipe wall adopts a "U"-shaped structure, which is impact resistant and pressure resistant. The foundation will not break even when the foundation is sinking, and it has strong resilience after deformation and has good adaptability to the foundation.

- Anti-aging: The pipe is usually black, which can withstand direct sunlight during storage and construction.

- Cold Resistance: The pipe will not be frozen, cracked, expanded and leaked in an environment of -60°C.

- Light Weight: It's easy to transport and easy to construct. The weight is 1/8 of the weight of the cement pipe. The buried pipe only needs an excavator and does not require large equipment.

- Convenient Connection: The pipes can be connected outside the ditch first, and pushed into the ditch with an excavator, reducing engineering time and costs.

- Superior Abrasion Resistance: It is more abrasion-resistant than steel pipes and cement pipes, and has a stronger capacity to transport domestic water waste slag.

- Superior Drainage Fluidity: smooth inside, reducing friction, and fast drainage.

- Economy: Low construction, management and maintenance costs.

- Environmental Impact: HDPE is a non-toxic raw material, harmless to the environment such as land, and can be recycled.

- Good Stability of The Pipeline System: The circular outer rib structure of the pipe not only increases the ring stiffness of the pipe, but also has root resistance, which solves the problems of tension and jacking caused by the longitudinal displacement of the pipe.

- Completely Reliable Ring Stiffness: Since the elastic modulus ratio of the two materials of steel and plastic is greater than 200, the weight ratio is greater than 7.85, compared with pure plastic pipes, steel belt reinforcement can easily make pipes (especially large diameter pipes) have Sufficient safe and reliable ring stiffness and relatively high stiffness-to-weight ratio.

Application Field

- Municipal Engineering: buried drainage and sewage pipes.

- Road Engineering: seepage and drainage pipes of railways and expressways.

- Industry: widely used in sewage pipes in the industrial field.

- Construction Engineering: building rainwater pipes, underground drainage pipes, sewage pipes, ventilation pipes, etc..

- Waste landfill sewage collection pipe.

- Large-scale port and wharf projects: drainage and sewage pipes for large-scale airports, ports, and wharf projects.

- Sports Venues: seepage and drainage pipes in sports venues such as golf courses and football fields.

- Water Conservancy Projects: the use of water source pipes, irrigation pipes, and water delivery and drainage of hydropower stations.

- Mine: mine ventilation, air supply, drainage, mud pipes.

- Communication Pipe: railway, highway communication, communication cable, optical cable protection pipe.

- Water Storage System: a water storage system that intercepts slow water flow.

- Agricultural Engineering: irrigation and drainage of farmland, orchard, tea garden and forest belt.

- Sea Water Conveying Pipe.

HDPE Plastic Steel Winding Pipe

Polyethylene plastic-steel winding pipe is made of steel-plastic composite special-shaped strip through spiral winding welding (extrusion welding on the lap surface), and its inner wall is smooth and flat. This kind of pipe has the advantages of corrosion resistance, light weight, easy installation, large flow rate, long life (50 years), etc. It can replace pipes made of high energy consumption materials (cement, cast iron, ceramics, etc.), and is an environmentally friendly green product.

Features

- Safe and Reliable Ring Stiffness: Compared with pure plastic pipes, reinforced steel belts are very easy to make pipes. Especially large-diameter pipes, it has enough safe and reliable ring stiffness.

- The Inner Wall is Smooth & The Flow Resistance is 20-30% Lower Than That of The Cement Pipe: The inner wall of the polyethylene (PE) pipe is smooth, the friction coefficient is small, and the sediment is not easy to accumulate in the pipe, and the friction resistance is almost unchanged after long-term use.

- Flexible or Non-leakage (Electrofusion Welding, Butt Welding) Connection, Good Sealing Performance and Environmental Protection Performance: The two sealing connection methods can be manually operated with simple tools. It does not require machinery. It is very simple and fast. It also achieves reliability and no leakage.

- Corrosion Resistance & Service Life Over 50 Years: The service life of high-density polyethylene (PE) pipes can be as long as 50 years.

- Light Weight, Few Joints, No Need for Large-scale Equipment, Easy Installation and Laying: Light weight, no large-scale lifting equipment is required for installation. The axial flexibility is good. The flatness and firmness of the bottom of the groove are lower when laying. The ability to withstand abnormal stress caused by improper installation is strong.

- Strong Ability to Resist Abnormal Sudden Load: The pipe can be elastically deformed to resolve the resulting stress. And it avoids leakage or damages at the pipe connection due to excessive stress and deformation.

- Competitive Comprehensive Cost: Combining the advantages of steel and plastic materials, the pipe has excellent comprehensive performance.

Application Field

- Municipal Engineering: Used as buried rainwater and sewage pipes.

- Road Engineering: Used as seepage and drainage pipes for railways and highways.

- Industry: Sewage pipes widely used in industrial fields.

- Construction Works: Used as building rainwater pipes, underground drainage pipes, sewage pipes, ventilation pipes, etc..

- Waste Landfill Sewage Collection Pipe

- Large-scale Port and Wharf Projects: Rainwater and sewage pipes for large-scale airports, ports, and wharf projects.

- Sports Venues: Used as seepage and drainage pipes for golf courses, football fields and other sports venues.

- Water Conservancy Projects: Used as water source pipes and irrigation pipes.

- Mine: Used as mine ventilation, air supply, drainage, and mud pipe.

- Communication Pipe: Railway, highway communication, communication cable, optical cable protection pipe, etc..

- Water Storage System: A water storage system used to intercept slow water flow.

- Agricultural Engineering: Used for irrigation of farmland, orchard, tea garden and forest belt.

- Sea Water Pipeline

- River Dredging